Introduction:

Wafer Process Control Equipment Market Size is expected to grow USD 13.33 Billion by 2032, at (CAGR) of 6.60% during the forecast period (2023 - 2032).

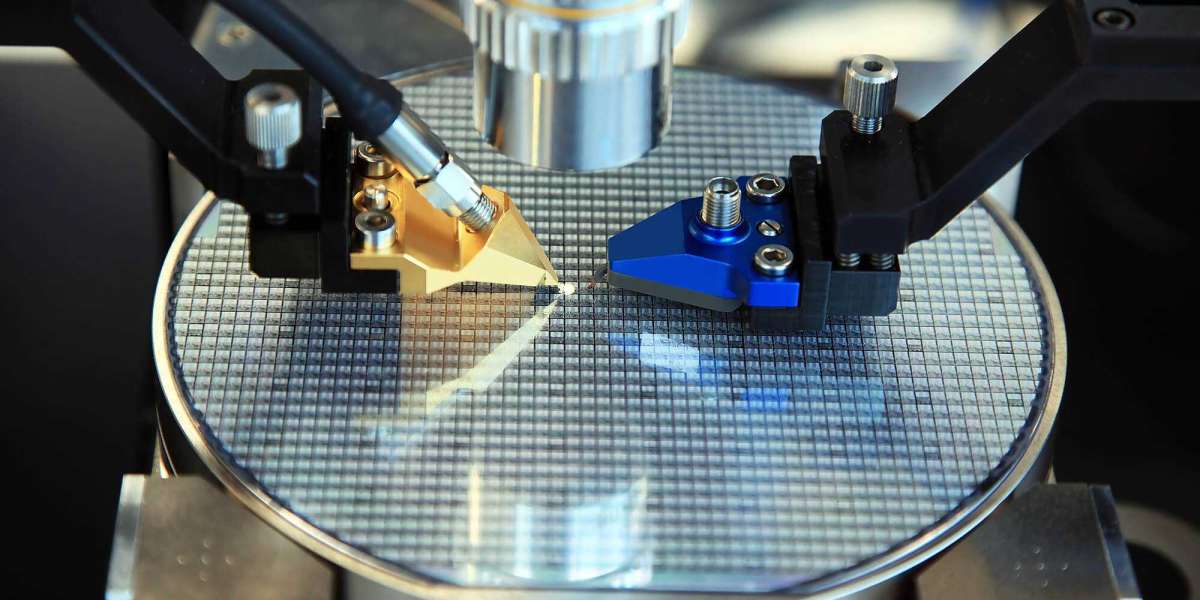

The wafer process control equipment market plays a pivotal role in ensuring the efficiency, accuracy, and reliability of semiconductor manufacturing processes. This article delves into the dynamics of the market, exploring key trends, growth drivers, challenges, and future prospects.

Analysis of Wafer Process Control Equipment:

Wafer process control equipment encompasses a range of instruments and systems used to monitor, analyze, and optimize various stages of semiconductor wafer fabrication processes. These processes include deposition, etching, lithography, ion implantation, and metrology, among others. The primary objective of process control equipment is to maintain tight tolerances, enhance yield, and ensure the production of high-quality semiconductor devices.

Key Market Trends:

- Rapid Technological Advancements: The semiconductor industry is characterized by continuous technological advancements, driving the demand for innovative process control equipment with higher precision, resolution, and throughput. Manufacturers are investing in research and development to introduce advanced features such as real-time monitoring, predictive maintenance, and machine learning algorithms.

- Increasing Adoption of Advanced Materials: With the advent of new materials such as gallium nitride (GaN), silicon carbide (SiC), and 2D materials like graphene, there is a growing need for process control equipment capable of handling diverse material properties and fabrication techniques. This trend is driven by the quest for higher performance, energy efficiency, and miniaturization in semiconductor devices.

- Focus on Yield Enhancement: Yield improvement remains a top priority for semiconductor manufacturers, particularly as wafer sizes increase and production costs escalate. Wafer process control equipment plays a crucial role in identifying and mitigating process variations, defects, and yield-limiting factors, thereby optimizing production efficiency and reducing scrap rates.

- Shift towards Industry 4.0 Practices: The integration of Industry 4.0 principles, including automation, connectivity, and data analytics, is reshaping the landscape of wafer process control equipment. Smart sensors, IoT-enabled devices, and cloud-based platforms are facilitating real-time monitoring, remote diagnostics, and predictive analytics, enabling proactive maintenance and process optimization.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/17180

Key Companies in the Wafer Process Control Equipment market include:

- Applied Materials, Inc.

- KLA Corporation

- ASML Holding NV

- Hitachi High-Tech Corporation

- Thermo Fisher Scientific

- ASM Technologies

- NXP Semiconductor

- Lasertec Corporation

- Toray Engineering

- Brodcom Inc.

Challenges Facing the Market:

- Complexity of Semiconductor Processes: Semiconductor manufacturing processes are becoming increasingly complex, with the integration of multiple process steps, materials, and equipment. This complexity poses challenges for process control equipment vendors in terms of compatibility, interoperability, and data integration across different process modules.

- Cost Constraints: The high cost of wafer process control equipment, coupled with the pressure to reduce semiconductor manufacturing costs, presents a significant challenge for both equipment suppliers and end-users. Manufacturers are under constant pressure to deliver cost-effective solutions without compromising on performance or reliability.

- Data Security and Privacy Concerns: As wafer process control equipment becomes more interconnected and data-driven, there are growing concerns regarding data security, intellectual property protection, and compliance with privacy regulations. Ensuring the confidentiality, integrity, and availability of sensitive manufacturing data is paramount to maintaining trust and credibility in the industry.

Future Outlook:

The wafer process control equipment market is poised for steady growth, driven by the ongoing expansion of the semiconductor industry, advancements in materials and manufacturing technologies, and the relentless pursuit of quality, efficiency, and productivity gains. Market players that can innovate, collaborate, and adapt to evolving industry requirements will be well-positioned to capitalize on emerging opportunities and shape the future of semiconductor manufacturing.

Read more article -

Power Management IC's Market Research Report – Forecast till 2032

Smartphone Display Market Research Report – Forecast till 2032

Human Centric Lightings Market Research Report – Forecast till 2032

VPX SBC Market Research Report – Forecast till 2032

3D Motion Capture System Market Research Report – Forecast till 2032