The global industrial gas turbine market size has been experiencing significant growth, with its size reaching about USD 22.31 billion in 2023. Projections indicate a continued upward trajectory, with the market expected to grow at a compound annual growth rate (CAGR) of about 3.5% during the forecast period 2024-2032. At the heart of this growth lies the relentless pursuit of efficiency in industrial gas turbine technology.

I. Historical Context

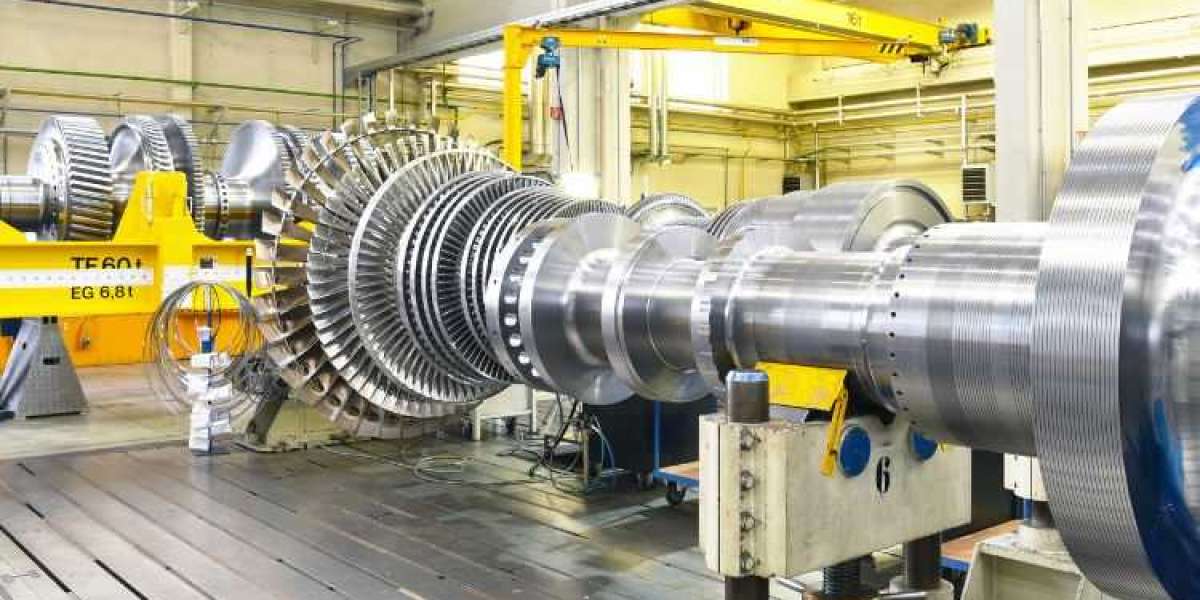

The evolution of industrial gas turbines spans several decades, marked by continuous innovation and engineering breakthroughs. Industrial gas turbines, also known as combustion turbines, are engines that convert natural gas or other liquid fuels into mechanical energy, primarily for electricity generation, industrial processes, and propulsion applications.

The history of industrial gas turbines dates back to the early 20th century when pioneers like Frank Whittle and Hans von Ohain laid the groundwork for modern gas turbine technology. Early gas turbines were relatively inefficient compared to contemporary standards, but they laid the foundation for subsequent advancements.

II. Factors Affecting Efficiency

Efficiency in industrial gas turbines is influenced by various factors, each playing a crucial role in determining overall performance:

Thermodynamic Principles: At its core, the efficiency of a gas turbine is governed by thermodynamic principles, including the Brayton cycle. Maximizing thermal efficiency involves optimizing the compression ratio, combustion process, and expansion ratio to extract the maximum amount of energy from the fuel.

Design Considerations: Turbine design plays a pivotal role in determining efficiency. Factors such as blade profile, airfoil shape, and clearance control impact turbine performance. Aerodynamic design optimizations aim to minimize losses and maximize energy extraction throughout the turbine stages.

Material Advancements: Advances in materials science have significantly contributed to improving turbine efficiency. High-temperature alloys, such as nickel-based superalloys and ceramic matrix composites, enable turbines to operate at elevated temperatures, enhancing thermal efficiency and power output.

III. Advancements in Gas Turbine Components

Key advancements in gas turbine components have played a pivotal role in enhancing efficiency and performance:

Turbine Blades and Vanes: Turbine blades and vanes are critical components responsible for extracting energy from the high-temperature, high-pressure gas stream. Advances in airfoil design, cooling technology, and manufacturing processes have enabled turbines to operate at higher inlet temperatures and pressures, improving thermal efficiency.

Compressor Technology: The compressor plays a crucial role in compressing air before combustion, thereby increasing pressure and energy density. Advancements in compressor design, such as aerodynamic optimization, variable geometry, and multi-stage compression, have improved overall efficiency and power output.

Combustor Design: Combustors are responsible for mixing fuel with compressed air and initiating the combustion process. Advanced combustor designs, such as lean-burn and diffusion flame combustors, optimize fuel-air mixing, combustion stability, and emissions control, thereby enhancing overall efficiency and environmental performance.

IV. Digitalization and Control Systems

Digitalization has revolutionized the way industrial gas turbines are monitored, controlled, and maintained. Advanced control systems, data analytics, and machine learning algorithms enable real-time performance optimization, predictive maintenance, and fault diagnostics.

Digital Twins: Digital twin technology creates virtual replicas of physical assets, allowing operators to simulate turbine performance under various operating conditions. By leveraging real-time data and predictive models, digital twins enable proactive maintenance planning, performance optimization, and risk management.

Predictive Maintenance Techniques: Predictive maintenance techniques utilize sensor data, machine learning algorithms, and predictive analytics to anticipate equipment failures and schedule maintenance activities proactively. By detecting early warning signs of potential issues, predictive maintenance minimizes downtime, reduces maintenance costs, and prolongs equipment lifespan.

Optimization Algorithms: Optimization algorithms continuously analyze operational data, weather forecasts, and market conditions to optimize turbine performance and dispatch strategies. By dynamically adjusting turbine parameters, such as load, fuel consumption, and operating conditions, optimization algorithms maximize efficiency, revenue, and grid stability.

V. Case Studies

Real-world case studies provide tangible examples of efficiency improvements achieved through the implementation of advanced turbine technology:

Example 1: Implementation of Advanced Gas Turbines in Power Plants:

- Case Study Description: A power generation company replaces aging turbines with advanced gas turbines featuring high-efficiency components and digital control systems.

- Results: The new turbines achieve significant fuel savings, emissions reductions, and operational flexibility, improving overall plant efficiency and profitability.

Example 2: Efficiency Improvements in Industrial Processes Using Gas Turbines:

- Case Study Description: An industrial facility integrates gas turbines into its manufacturing processes to generate onsite power and heat.

- Results: By utilizing waste heat for industrial processes, the facility improves energy efficiency, reduces reliance on grid power, and lowers operating costs, enhancing overall competitiveness.

Example 3: Retrofitting Older Turbines for Enhanced Efficiency:

- Case Study Description: A utility company retrofits older gas turbines with advanced components, combustion systems, and digital control upgrades.

- Results: The retrofit improves turbine performance, reliability, and emissions compliance, extending the lifespan of existing assets and deferring capital investments in new equipment.

VI. Environmental Considerations

Efficiency advancements in industrial gas turbines are closely linked to environmental considerations, including emissions reduction, fuel flexibility, and sustainability:

Reduction of Emissions: Gas turbines are subject to stringent emissions regulations, necessitating continuous improvements in combustion technology, emissions control systems, and fuel flexibility. Low-NOx combustion systems, dry low emissions (DLE) combustors, and selective catalytic reduction (SCR) systems are employed to minimize emissions of nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter.

Role of Alternative Fuels: The adoption of alternative fuels, such as natural gas, biogas, hydrogen, and syngas, plays a crucial role in reducing greenhouse gas emissions and enhancing fuel flexibility. Dual-fuel combustion systems, hydrogen-ready turbines, and co-firing technologies enable turbines to utilize a diverse range of fuels while maintaining high efficiency and performance.

VII. Future Trends and Challenges

Looking ahead, the industrial gas turbine industry faces both opportunities and challenges as it seeks to further enhance efficiency and sustainability:

Potential for Further Efficiency Gains: Advancements in turbine materials, aerodynamics, and combustion technology hold the potential for further efficiency gains, enabling turbines to operate at even higher temperatures and pressures while maintaining reliability and emissions compliance.

Integration with Renewable Energy Sources: The integration of industrial gas turbines with renewable energy sources, such as solar and wind power, presents opportunities for hybrid energy systems and grid stabilization. Combined cycle power plants, hybrid renewable-fossil fuel systems, and energy storage solutions enable seamless integration of intermittent renewables with dispatchable gas turbine power generation.