Introduction:

Intrinsically Safe Equipment Market Size is expected to grow USD 5.70 Billion by 2032, at (CAGR) of 7.80% during the forecast period (2023 - 2032).

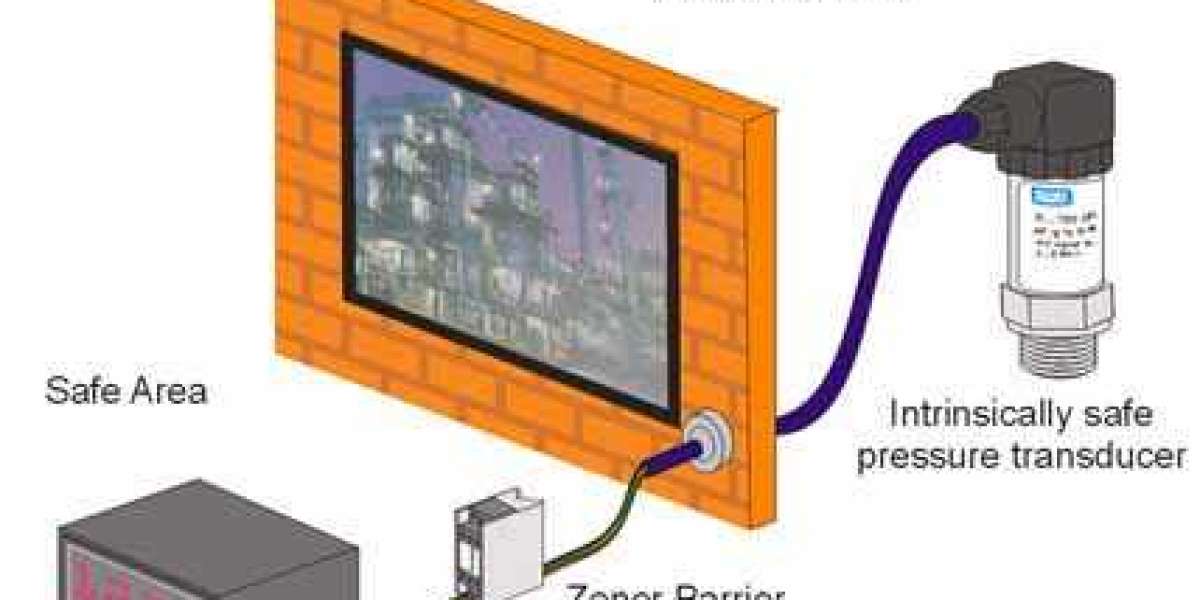

In hazardous environments where the risk of explosion or fire is present, ensuring the safety of workers and equipment is paramount. Intrinsically safe equipment, designed to prevent the ignition of hazardous atmospheres, plays a crucial role in industries such as oil and gas, chemical processing, mining, and pharmaceuticals. The intrinsically safe equipment market, driven by stringent safety regulations and the need for risk mitigation, is experiencing steady growth. In this article, we delve into the dynamics of the intrinsically safe equipment market, emerging trends, and future prospects.

Market Overview:

The global intrinsically safe equipment market has witnessed significant growth in recent years, propelled by a growing awareness of workplace safety regulations and the need for explosion-proof equipment. According to industry reports, the market was valued at over USD 4 billion in 2020 and is projected to continue its upward trajectory in the coming years.

Intrinsically Safe Equipment Market Analysis:

- Stringent Safety Regulations: Government regulations and industry standards mandate the use of intrinsically safe equipment in hazardous environments to prevent accidents and ensure worker safety. Compliance with standards such as ATEX, IECEx, and NEC (National Electrical Code) drives the adoption of intrinsically safe equipment across various industries.

- Rising Awareness of Occupational Hazards: Increasing awareness of the potential risks associated with hazardous environments has prompted companies to invest in intrinsically safe equipment to mitigate the risk of explosions, fires, and other accidents. The emphasis on employee safety and corporate responsibility further fuels the demand for intrinsically safe solutions.

- Technological Advancements: Advances in sensor technology, electronics, and materials science have led to the development of more sophisticated intrinsically safe equipment with enhanced performance, reliability, and functionality. Innovations such as wireless communication capabilities, IoT integration, and remote monitoring enhance the efficiency and effectiveness of intrinsically safe solutions.

- Expansion of End-Use Industries: The expansion of industries such as oil and gas exploration, chemical processing, and mining in emerging markets drives the demand for intrinsically safe equipment. As these industries expand into remote and hazardous environments, the need for reliable safety solutions becomes increasingly critical.

Intrinsically Safe Equipment Market Trends:

- Integration of IoT and IIoT: The integration of Internet of Things (IoT) and Industrial Internet of Things (IIoT) technologies enables real-time monitoring, predictive maintenance, and data-driven decision-making in hazardous environments. Intrinsically safe equipment equipped with IoT capabilities facilitates remote monitoring of equipment performance and environmental conditions, enhancing safety and operational efficiency.

- Modular and Customizable Solutions: Increasing demand for flexibility and scalability drives the adoption of modular and customizable intrinsically safe equipment solutions. Manufacturers offer a range of modular components and accessories that can be tailored to specific application requirements, allowing for greater versatility and cost-effectiveness.

- Enhanced Connectivity and Communication: With the proliferation of wireless communication technologies such as Bluetooth, Wi-Fi, and Zigbee, intrinsically safe equipment is becoming more connected and interoperable. Wireless communication capabilities enable seamless integration with existing infrastructure and enable real-time data exchange between devices, improving situational awareness and response capabilities.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/11895

Intrinsically Safe Equipment market Companies include:

- Pepperl + Fuchs

- Fluke Corporation

- OMEGA Engineering (Spectris PLC)

- Stahl AG

- RAE Systems (Honeywell)

- Eaton Corporation

- CorDEX Instruments Ltd.

- Bayco Products, Inc.

- Kyland Technology Co., Ltd.

- Banner Engineering Corp.

- Georgin

Future Outlook:

The intrinsically safe equipment market share is poised for sustained growth, driven by increasing regulatory requirements, growing awareness of occupational hazards, and technological advancements. As industries strive to enhance workplace safety, the demand for intrinsically safe solutions will continue to rise. Additionally, the integration of advanced technologies such as IoT, IIoT, and wireless communication will further propel the evolution of intrinsically safe equipment, enabling safer and more efficient operations in hazardous environments.

Get a regional report on US intrinsically safe equipment market