Introduction:

Electronic Manufacturing Services Market Size is expected to grow from USD 542.09 Billion in 2023 to USD 813.2 Billion by 2032, at (CAGR) of 5.20% during the forecast period (2023 - 2032).

The Electronic Manufacturing Services (EMS) market plays a vital role in the global electronics industry, providing a wide range of services to original equipment manufacturers (OEMs) to streamline their production processes and meet market demands. From design and engineering to assembly and testing, EMS providers offer comprehensive solutions that enable OEMs to bring innovative electronic products to market efficiently and cost-effectively. This article delves into the dynamics of the EMS market, exploring key trends, major players, and factors driving its growth.

Understanding Electronic Manufacturing Services (EMS):

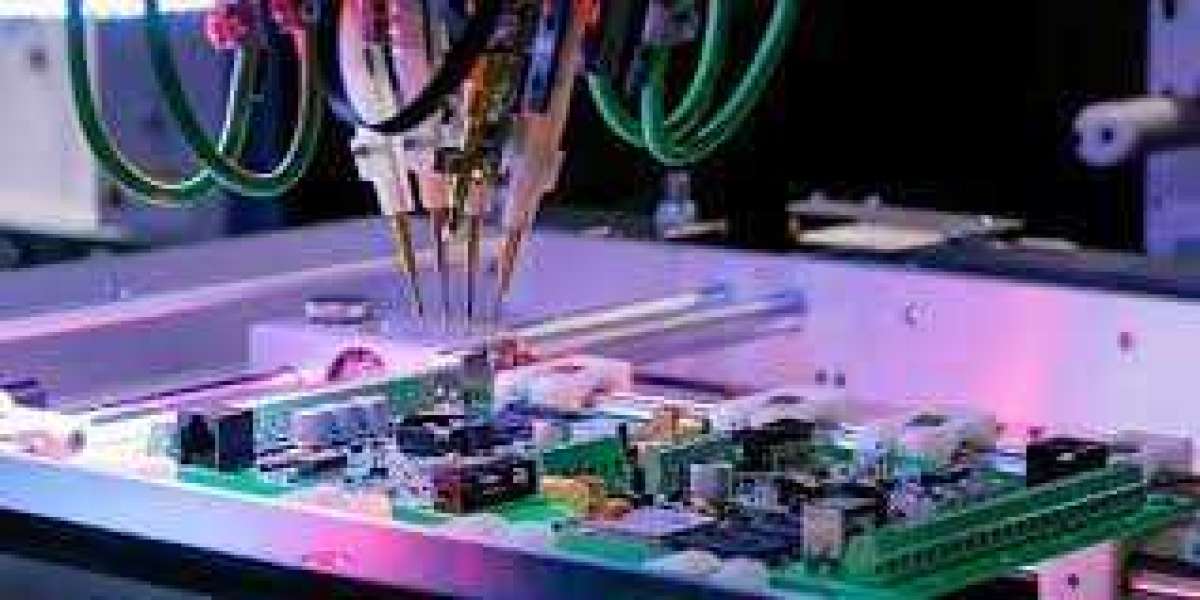

Electronic Manufacturing Services (EMS) encompass a broad spectrum of services provided by specialized companies to support the design, manufacturing, and testing of electronic products. These services typically include product design and development, component sourcing and procurement, PCB assembly, system integration, testing and quality assurance, logistics, and after-sales support. EMS providers serve a diverse range of industries, including consumer electronics, automotive, aerospace, healthcare, telecommunications, and industrial automation.

Get a free sample @ https://www.marketresearchfuture.com/sample_request/10873

Electronic Manufacturing Services Market Analysis and Growth Drivers:

Several factors contribute to the growth of the Electronic Manufacturing Services market:

- Outsourcing Trends: Increasingly, OEMs are outsourcing their manufacturing operations to EMS providers to leverage their expertise, resources, and economies of scale. Outsourcing enables OEMs to focus on core competencies such as product design, marketing, and sales, while EMS providers handle the complexities of manufacturing, supply chain management, and production optimization.

- Cost Efficiency: EMS providers offer cost-effective manufacturing solutions by leveraging their global supply chain networks, operational efficiencies, and volume purchasing power. By consolidating production volumes across multiple customers and leveraging economies of scale, EMS providers can achieve cost savings in materials procurement, labor, and overhead costs, resulting in lower manufacturing costs for OEMs.

- Time-to-Market Pressure: In today's fast-paced market environment, OEMs face intense pressure to bring new products to market quickly to capitalize on emerging opportunities and stay ahead of competitors. EMS providers offer flexible manufacturing solutions and rapid prototyping capabilities that enable OEMs to accelerate product development cycles, reduce time-to-market, and respond swiftly to changing customer demands.

- Technological Advancements: Advances in technology, such as Industry 4.0, automation, robotics, and artificial intelligence, are transforming the EMS landscape, enabling greater efficiency, flexibility, and customization in manufacturing operations. EMS providers are investing in automation and digitalization initiatives to optimize production processes, improve quality control, and enhance operational performance, driving innovation and competitiveness in the market.

Electronic Manufacturing Services Market Key Trends and Market Landscape:

The Electronic Manufacturing Services market is characterized by the presence of leading global players, regional providers, and specialized niche players. Key players in the market include:

Electronic Manufacturing Services market Companies include:

- Sanmina Corporation (U.S.)

- Hon Hai Precision Industry Co. Ltd (Foxconn) (Taiwan)

- Benchmark Electronics Inc. (U.S.)

- Flex Ltd (Singapore)

- Jabil Inc. (U.S.)

- Celestica Inc. (Canada)

- Wistron Corporation (Taiwan)

- Plexus Corporation (U.S.)

- Fabrinet (Thailand)

- COMPAL Inc. (Taiwan)

These companies offer a wide range of EMS solutions and services tailored to the specific needs and requirements of their customers across various industries and market segments. Additionally, the EMS market is characterized by intense competition, rapid technological advancements, and ongoing consolidation as players seek to expand their market presence, enhance capabilities, and address emerging customer demands.

Applications and Industry Verticals:

Electronic Manufacturing Services find applications across diverse industries and verticals, including:

- Consumer Electronics: EMS providers support the design, manufacturing, and assembly of consumer electronics products such as smartphones, tablets, laptops, smart TVs, and home appliances. These products require high-volume production, fast turnaround times, and stringent quality control to meet consumer expectations and market demands.

- Automotive: In the automotive industry, EMS providers supply electronic components, modules, and systems for vehicles, including infotainment systems, advanced driver assistance systems (ADAS), engine control units (ECUs), and in-car connectivity solutions. These products require robust design, reliability, and compliance with automotive standards and regulations.

- Aerospace and Defense: EMS providers serve the aerospace and defense sector by supplying mission-critical electronic components, avionics systems, communication systems, and military-grade equipment. These products require stringent quality control, adherence to safety and security standards, and compliance with regulatory requirements for reliability and performance in harsh environments.

- Healthcare and Medical Devices: In the healthcare industry, EMS providers manufacture electronic components and devices for medical diagnostics, imaging systems, patient monitoring, and therapeutic equipment. These products require precision engineering, reliability, and compliance with regulatory standards such as ISO 13485 and FDA regulations for quality assurance and patient safety.

Future Outlook and Trends:

The Electronic Manufacturing Services market is poised for continued growth and evolution, driven by technological advancements, shifting market dynamics, and emerging industry trends. Key trends shaping the future of the EMS market include:

- Digital Transformation: EMS providers are embracing digital transformation initiatives, including automation, robotics, IoT, and data analytics, to optimize manufacturing processes, improve productivity, and enhance operational efficiency. Digitalization enables real-time monitoring, predictive maintenance, and adaptive manufacturing capabilities that enable EMS providers to respond swiftly to changing customer demands and market conditions.

- Sustainable Manufacturing Practices: There is a growing emphasis on sustainable manufacturing practices and environmental stewardship in the EMS industry. EMS providers are adopting green manufacturing technologies, recycling initiatives, and renewable energy solutions to minimize waste, reduce carbon footprint, and comply with environmental regulations while meeting customer expectations for sustainability and corporate social responsibility (CSR).

- Supply Chain Resilience: The COVID-19 pandemic highlighted the importance of supply chain resilience and risk mitigation in the EMS industry. EMS providers are diversifying their supplier base, optimizing inventory management, and implementing contingency plans to mitigate supply chain disruptions and ensure business continuity in the face of unforeseen events such as natural disasters, geopolitical tensions, and global pandemics.

- Customization and Personalization: As consumer preferences become increasingly diverse and demand for personalized products grows, EMS providers are focusing on customization and personalization capabilities to meet the unique needs and requirements of their customers. Advanced manufacturing technologies such as 3D printing, additive manufacturing, and flexible electronics enable EMS providers to offer tailored solutions and mass customization services that differentiate their offerings and drive customer satisfaction and loyalty.

Get a regional report on US Electronic Manufacturing Services Market